ZHEJIANG BRIDGOLD COPPER TECH CO.,LTD

Booth Number: Hall N4 - N4C18

Add EP Wechat for consultation

Share this page

Exhibitor E-invitation

Invitation / Product Poster

FLEXIBLE COPPER BRAIDED BUSBARS

New Products / New Technology

MATERIAL

T2 (C11000) copper wire, single wire diameter 0.05-0.30mm

SURFACE

No plating, tin plating, nickel plating or silver plating

PROCESS

Flat type or round type copper braids are braided by high-speed wire braiding machines, both ends are pressed with seamless copper ferrules into a contact area, or mounted with lugs as installation connecting points.

FEATURES

Flexible copper wire connectors own excellent flexible conductivity, especially suitable for new energy vehicle power parts with large vibration frequency.

Customization as per drawing.

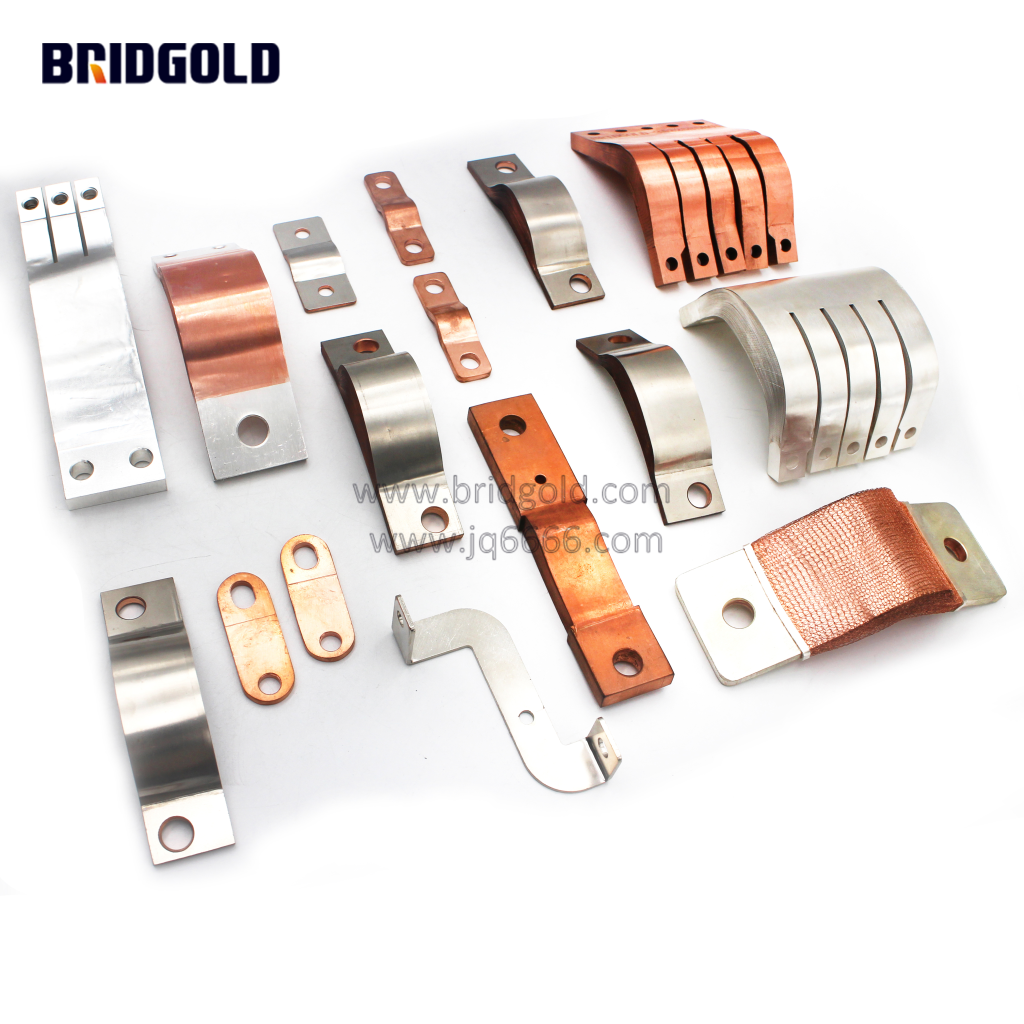

FLEXIBLE LAMINATED COPPER BUSBARS

New Products / New Technology

MATERIAL

T2 (C11000) copper foil, single foil thickness 0.05-0.20mm

TU2 (C10100) copper foil, single foil thickness 0.03mm-0.30mm

WELDING METHOD

Molecular Diffusion Welding Method: adopt special welding machine to press and heat the foils with each other according to the welding area, then the contact area is shaped. This avoids higher contact resistance problem by other welding methods.

Silver Brazing Method: weld the workpieces of different shapes into one piece by filling silver braze material into the gap of the workpieces. This welding method is used to weld the flexible laminated connectors of non-standard shape to realize the installation and to reduce the processing cost.

FEATURES

Flexible laminated copper connectors own excellent flexible conductivity. The press welding method ensures the connectors with better electric current concentrating effect, and the overload capacity of flexible laminated copper connectors is 1.2 times that of hard copper bus bars. The product eliminates the hidden security risk due to the damage to contact electrodes caused by uneven installation surface and its stress effect, and meanwhile, avoids the fasteners from getting loose during the running process of the vehicles, which may cause bad conductivity of the battery pack.

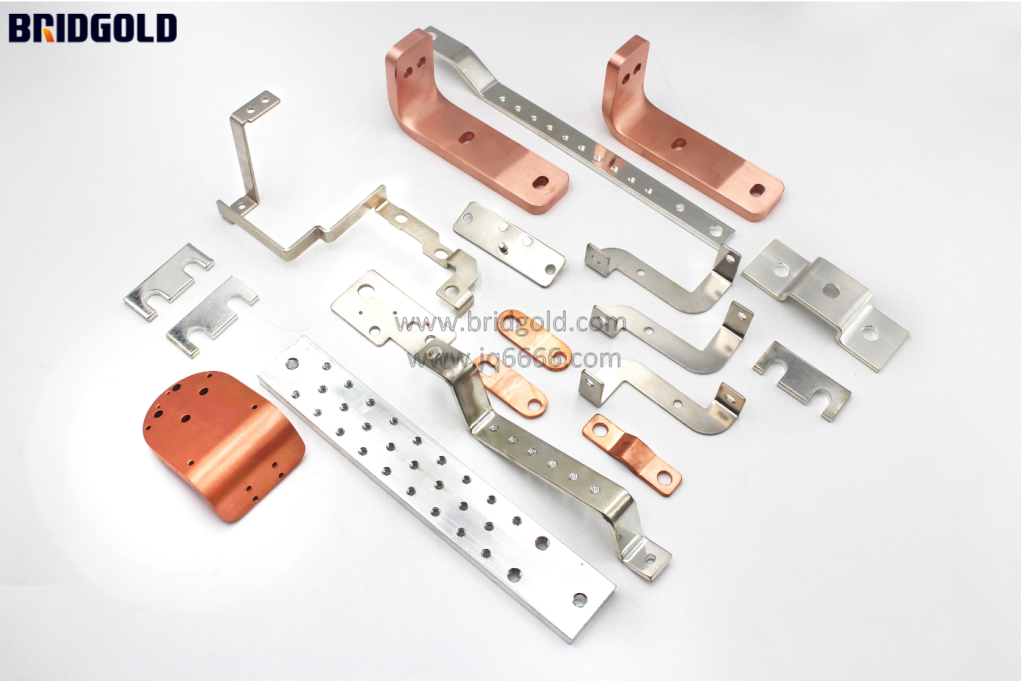

RIGID COPPER BUSBAR

New Products / New Technology

Material

T2 (C11000) copper bar

TU2 (C10100) copper bar

FEATURES

Excellent conductivity for electrical, vehicle and mechanical equipment which need connection of standard type and non-standard type, and specially for installation environment with high fire protection requirement, large load fluctuation and high humidity.

Customization as per drawing.

思源黑体预加载(勿删): ZHEJIANG BRIDGOLD COPPER TECH CO.,LTD