HANGZHOU KAIMA SIGNAGE CO., LTD.

Booth Number: Hall N4 - N4L41

Add EP Wechat for consultation

Share this page

Exhibitor E-invitation

Invitation / Product Poster

WIRING NUMBER MACHINE CONSUMABLES

The company produces and supplies various types of label machine consumables, including ribbons, label stickers, number tubes, heat shrink tubes, and label machine accessories. With our own factory, the production volume is considerable and the quality is guaranteed. It is your perfect choice.

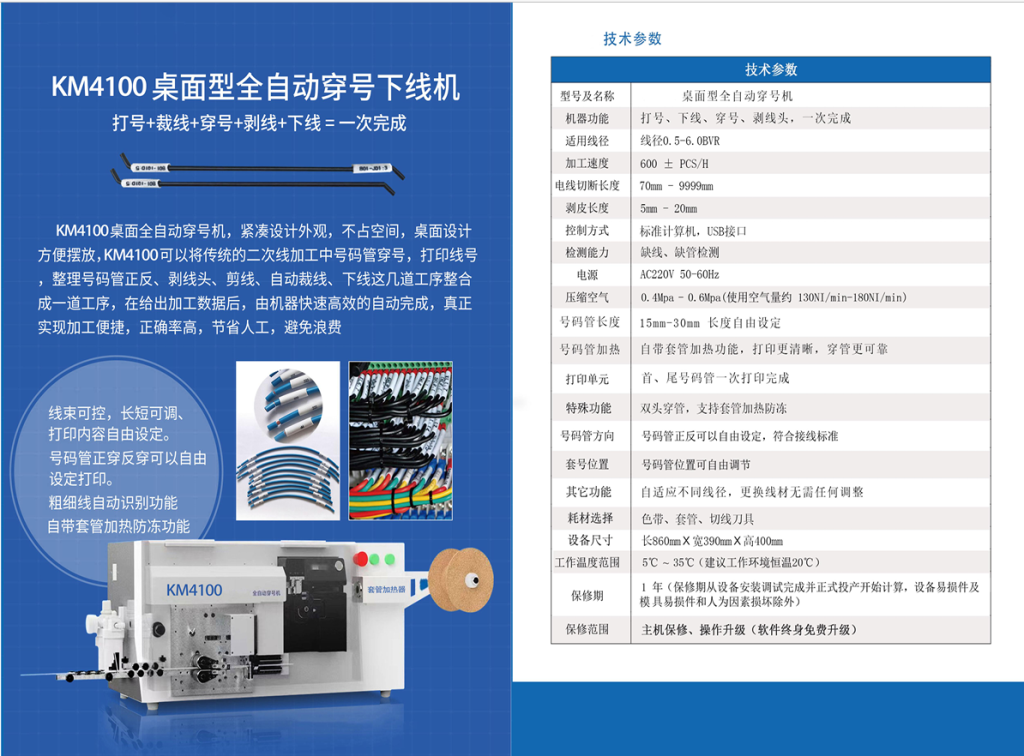

DESKTOP-TYPE FULLY AUTOMATIC LABEL DISPENSING AND OFF-LINE MACHINE

The KM4100 desktop fully automatic numbering machine features a compact design with no space occupation. Its desktop layout is convenient for placement. KM4100 can integrate the traditional secondary wire processing steps of numbering tubes, printing line numbers, arranging the numbers on the tubes, stripping the wire ends, cutting the wires, automatically cutting the wires, and unthreading into a single process. After providing the processing data, the machine can quickly and efficiently complete the entire process automatically, truly achieving convenient processing, high accuracy, labor saving, and waste avoidance.

FULLY AUTOMATIC WIRING HARNESS PROCESSING EQUIPMENT

Fully automatic wiring processing equipment: marking + unloading + threading + double pressing = all completed in one step. Adaptable terminal types: granular pre-insulated, IT, UT, OT, etc. Save manpower, process quickly, and enhance efficiency. Strengthening the structure, improving the quality, and reducing waste.

思源黑体预加载(勿删): HANGZHOU KAIMA SIGNAGE CO., LTD.